Porter Contract

The Porter Contract refers to the contract commissioned by Rev. Edward Porter and Levi Porter for Eli Terry to produce 4,000 clocks in three years. The exact date that the contract was commissioned is unknown, but land purchases by Terry can suggest that it was commissioned in the summer of 1806. The contract is the first to credit a founding father of the Industrial Revolution in the United States, taking into account that both interchangeable parts, and mass production occurred.

Eli Terry began producing wooden clocks at Plymouth (Watertown) in 1793. In 1795, Terry developed a Milling machine to develop Interchangeable parts. Terry used this machine to produce clocks until the Porter contract in 1806. Milling machines resulted in a low yield of clock parts, and wasted raw material. When the Porter Contract was commissioned, Terry developed a cutting machine which would produce a higher, secure yield.

To set up a facility to complete the contract, Terry purchased a mill from Calvin Hoadley of Waterbury on July 21, 1806. Terry hired Silas Hoadley and Seth Thomas (clockmaker) to work the facilities during the contract. It is believed that no clocks were produced until 1807, considering that Terry spent the first year building the facilities and machinery.[1]

The success in the porter contract resulted in a change in the American Clock Industry. This was the first example of mass production using interchangeable parts. The average annual yield of clocks produced at the time by other clock makers did not exceed a few dozen. Chauncey Jerome, who apprenticed Eli Terry learned mass production techniques and became the first person to mass produce brass shelf clocks in 1840. Jerome's annual yield in 1840 was 20,000 clocks; and later 200,000 clocks annually at New Haven.[2]

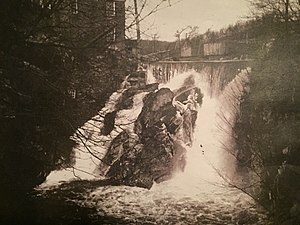

After the contract, Terry sold his factory to Hoadley and Thomas, and relocated to the Naugatuck River in Plymouth Hollow, where he mass produced the first shelf clock. Thomas and Hoadley operated the factory until 1815, when Seth Thomas opened his own factory at Plymouth Hollow. Silas Hoadley remained at the factory which he operated until his retirement in 1849. The factory building was later used by the Hancock Manufacturing Company, and was demolished in the 1940's. A house now stands on the factory foundation, but other foundations of the factory complex as well as the 60 foot waterfall, waterwheel pit, and canals are still existent.

References[edit]

- ↑ Roberts, Kenneth D., and Snowden Taylor. Eli Terry and the Connecticut Shelf Clock. Ken Roberts Publishing, 1994.

- ↑ Chauncey Jerome: https://archive.org/stream/historyofamerica00jero#page/n5/mode/2up History of the American Clock Business for the Past Sixty Years, and Life of Chauncey Jerome]. Barnum’s connection with the Yankee Clock Business, Publisher: F. C. Dayton, New Haven CT 1860

This article "Porter Contract" is from Wikipedia. The list of its authors can be seen in its historical and/or the page Edithistory:Porter Contract. Articles copied from Draft Namespace on Wikipedia could be seen on the Draft Namespace of Wikipedia and not main one.