Railroad Loading Gauge in North America

A loading gauge defines the maximum height, width and other criteria for railway vehicles and their loads to ensure that they can pass safely through tunnels and under bridges, and keep clear of trackside buildings and structures.[1] Two sections of track that are both standard gauge may in fact have loading gauges vary significantly from each other - loading gauge is not the same as track gauge.

Overview[edit]

The loading gauge restricts the size of passenger coaches, goods wagons (freight cars) and shipping containers that can travel on a section of railway track. It varies across the world and often within a single railway system. Over time there has been a trend towards larger loading gauges and more standardization of gauges; some older lines have had their structure gauges enhanced by raising bridges, increasing the height and width of tunnels and making other necessary alterations. Containerization and a trend towards larger shipping containers has led rail companies to increase structure gauges to compete effectively with road haulage.

The term "loading gauge" can also refer to a physical structure, sometimes using electronic detectors using light beams on an arm or gantry placed over the exit lines of goods yards or at the entry point to a restricted part of a network. The devices ensure that loads stacked on open or flat wagons stay within the height/shape limits of the line's bridges and tunnels, and prevent out-of-gauge rolling stock entering a stretch of line with a smaller loading gauge. Compliance with a loading gauge can be checked with a clearance car. In the past, these were simple wooden frames or physical feelers mounted on rolling stock. More recently, laser beams are used.

The loading gauge is the maximum size of rolling stock. This is distinct from the structure gauge, which is the minimum size of bridges and tunnels, and must be larger to allow for engineering tolerances and car motion. The difference between the two is called the clearance. The terms "dynamic envelope" or "kinematic envelope" – which include factors such as suspension travel, overhang on curves (at both ends and middle) and lateral motion on the track – are sometimes used in place of loading gauge.[citation needed]

The height of platforms is also a consideration for the loading gauge of passenger trains. Where the two are not directly compatible, stairs may be required, which will increase loading times. Where long carriages are used at a curved platform, there will be gaps between the platform and the carriage door, causing risk. Problems increase where trains of several different loading gauges and train floor heights use (or even must pass without stopping at) the same platform.

The size of load that can be carried on a railway of a particular gauge is also influenced by the design of the rolling stock. Low-deck rolling stock can sometimes be used to carry taller 9 ft 6 in (2.9 m) shipping containers on lower gauge lines although their low-deck rolling stock cannot then carry as many containers.

Rapid Transit (metro) railways generally have a very small loading gauge, which reduces the cost of tunnel construction. These systems only use their own specialized rolling stock.

History[edit]

Most 1st generation North American underground rapid transit systems were built in the early 1900s. The cost and danger of tunneling during this era gave a strong incentive use vehicles built for small tunnels, rather than build bigger tunnels to fit standard size railcars. Additionally, the difficulties of using steam power in underground tunnels already nearly necessitated the dramatic deviation from standard construction in order to make the trains electrified. Combined, these factors led designers to see little benefit to constructing their tunnels to fit standard railcars. The designers saw more benefit in tailoring the rolling stock and tunnel dimensions to the unique situations of each city, rather than using the same standard as neighboring cities whose rolling stock would be highly unlikely to ever need to use their neighbor's tracks.[citation needed] Rapid Transit trains have noticeably and considerably smaller loading gauges and smaller interiors, despite the track being the same standard gauge as almost all of the rest of railroad track in North America.

Even within the same city, rapid transit lines were often optimized for their own unique situations at the expense of being compatible with each other, for various reasons. For example, New York City's system was started by multiple competing private companies before eventually being unified and expanded upon. In this case, the standards were deliberately not compatible in order to prevent a competitor from surreptitiously using their tunnels.[citation needed] Boston's system was has no interoperability between lines - the Orange line was built to relatively standard dimensions, the Red line was built extra-large in order to improve capacity and future-proof the line, meanwhile the Blue line is built upon upgrades to old trolley tunnels and must among other be short enough to make the same tight turns as the trolleys, and the Green Line tunnels are still used for streetcars to this day.

The 2nd generation of North American rapid transit systems did not occur until after a gap of roughly half a decade, beginning in the 1970s. Substantial improvements in technology occurred during this gap. Designers of second-generation systems saw that 1st generation systems were often unable to upgrade to much - desired improvements due to the constraints of their existing infrastructure. 2nd generation system designers often saw more benefit in avoiding these problems from the outset than from economies of scale for using the same standards. For example, the developers of Bay Area Rapid Transit felt that the benefit of wider, higher capacity trains that broad gauge allowed outweighed the additional cost of using a non-standard track gauge.

The lack of standardization among North American rapid transit systems results in increased costs for purchasing trains, as they must be specifically designed for the individual network, rather than being purchased "off-the-shelf".

Standard loading gauges for standard track gauge lines[edit]

Freight[edit]

The American loading gauge for freight cars on the North American rail network is generally based on standards set by the Association of American Railroads (AAR) Mechanical Division.[2] The most widespread standards are AAR Plate B and AAR Plate C, but higher loading gauges have been introduced on major routes outside urban centers to accommodate rolling stock that makes better economic use of the network, such as auto carriers, hi-cube boxcars, and double-stack container loads.[3]The maximum width of 10 ft 8 in (3.25 m) on 41 ft 3 in (12.57 m) and 46 ft 3 in (14.10 m) truck centers is valid on a 475 ft (144.78 m) radius curve.[2]

Listed here are the maximum heights and widths for cars. However, the specification in each plate shows a car cross-section that is chamfered at the top and bottom, meaning that a compliant car is not permitted to fill an entire rectangle of the maximum height and width.[4]

| Plate | Width | Height | Truck centers | Comments | Image | |||

|---|---|---|---|---|---|---|---|---|

| ft in | m | ft in | m | ft in | m | |||

| B | 10 8 | 3.25 | 15 1 | 4.60 | 41 3 | 12.57 | For longer truck centers, the width is decreased according to graph AAR Plate B-1 on a 475 ft (144.78 m) radius curve[2] |  |

| C | 10 8 | 3.25 | 15 6 | 4.72 | 46 3 | 14.10 | For longer truck centers, the width is decreased according to graph AAR Plate C-1 on a 475 ft (144.78 m) radius curve[2] |  |

| D | 10 8 | 3.25 | 15 9 | 4.80 | 46 3 | 14.10 | As with Plate C but 3 in (76 mm) taller than Plate C, and the car cross-section is larger at the top. For longer truck centers, the width is decreased according to graph AAR Plate C-1[2]. The top of rail clearance is 2 3⁄4 in (70 mm) as in other Plates except Plate-E |  |

| E | 10 8 | 3.25 | 15 9 | 4.80 | 46 3 | 14.10 | As with Plate C but 3 in (76 mm) taller than Plate C, and the car cross-section is larger at the top. The top of rail clearance is only 2 1⁄2 in (64 mm) instead of 2 3⁄4 in (70 mm) as in other Plates. Hence 15 feet 3 inches (4.648 m) vertical instead of 15 feet 2 7⁄8 inches (4.645 m) |  |

| F | 10 8 | 3.25 | 17 0 | 5.18 | 46 3 | 14.10 | As with Plate C but 18 in (457 mm) taller than Plate C and 15 in (381 mm) taller than plate E, and the car cross-section is larger at the top than plate E |  |

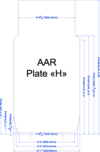

| H | 10 8 | 3.25 | 20 2 | 6.15 | 62 7 | 19.08 | e.g. double stacked containers[5] in well cars |

|

| J | 9 11 3⁄8 | 3.03 | 66 | 20.12 | e.g. 89-foot (27.1 m) long flatcars[7][8] | |||

| K | 10 0 | 3.05 | 20 2 | 6.15 | 64 | 19.51 | e.g. Autorack (road vehicles on trains)[9][10] | at center of car |

| K | 10 8 | 3.25 | 20 2 | 6.15 | 64 | 19.51 | e.g. Autorack (road vehicles on trains)[11][12] | at ends of car |

Technically, Plate B is still the maximum[clarification needed][2] and the circulation of Plate C is somewhat restricted. The prevalence of excess-height rolling stock, at first ~18 ft (5.5 m) piggybacks and hicube boxcars, then later autoracks, airplane-parts cars, and flatcars for hauling Boeing 737 fuselages, as well as 20 ft 2 in (6.15 m) high double-stacked containers in container well cars, has been increasing. This means that most, if not all, lines are now designed for a higher loading gauge. The width of these extra-height cars is covered by Plate C-1.[2]

All the Class I rail companies have invested in longterm projects to increase clearances to allow double stack freight. The mainline North American rail networks of the Union Pacific, the BNSF, the Canadian National, and the Canadian Pacific, have already been upgraded to Plate K. This represents over 60% of the Class I rail network.[13]

Passenger service[edit]

The old standard North American passenger railcar is 10 ft 6 in (3.20 m) wide by 14 ft 6 in (4.42 m) high and measures 85 ft 0 in (25.91 m) over coupler pulling faces with 59 ft 6 in (18.14 m) truck centers, or 86 ft 0 in (26.21 m) over coupler pulling faces with 60 ft 0 in (18.29 m) truck centers. In the 1940s and 1950s, the American passenger car loading gauge was increased to a 16 ft 6 in (5.03 m) height throughout most of the country outside the Northeast, to accommodate dome cars and later Superliners and other double-decker commuter trains. Bilevel and Hi-level passenger cars have been in use since the 1950s, and new passenger equipment with a height of 19 ft 9 1⁄2 in (6.03 m) has been built for use in Alaska and the Canadian Rockies. See Bilevel rail car. The structure gauge of the Mount Royal Tunnel limits the height of bilevel cars to 14 feet 6 inches (4.42 m).[14]

New York City Subway[edit]

The New York City Subway is an amalgamation of three former constituent companies, and while all are standard gauge, inconsistencies in loading gauge prevent cars from the former BMT and IND systems (B Division) from running on the lines of the former IRT system (A Division), and vice versa. This is mainly because IRT tunnels and stations are approximately 1 foot (305 mm) narrower than the others, meaning that IRT cars running on the BMT or IND lines would have platform gaps of over 8 inches (203 mm) between the train and some platforms, whereas BMT and IND cars would not even fit into an IRT station without hitting the platform edge. Taking this into account, all maintenance vehicles are built to IRT loading gauge so that they can be operated over the entire network, and employees are responsible for minding the gap.

Another inconsistency is the maximum permissible railcar length. Cars in the former IRT system are 51 feet (15.54 m) as of December 2013[update], but can be as long as 64 feet (19.51 m). Railcars in the former BMT and IND can be longer: on the former Eastern Division, the cars are limited to 60 feet (18.29 m), while on the rest of the BMT and IND lines plus the Staten Island Railway (which uses modified IND stock) the cars may be as long as 75 feet (22.86 m).[15][16]

Boston (MBTA)[edit]

The MBTA's rapid transit system is composed of four unique subway lines; while all lines are standard gauge, inconsistencies in loading gauge, electrification, and platform height prevent trains on one line from being used on another. The first segment of the Green Line (known as the Tremont Street Subway) was constructed in 1897 to take the streetcars off Boston's busy downtown streets. When the Blue Line opened in 1904, it only ran streetcar services; the line was converted to rapid transit in 1924 due to high passenger loads, but the tight clearances in the tunnel under the Boston Harbor required narrower and shorter rapid transit cars.[17] The Orange Line was originally built in 1901 to accommodate heavy rail transit cars of higher capacity than streetcars. The Red Line was opened in 1912, designed to handle what were for a time the largest underground transit cars in the world.[18]:127

Los Angeles (LACMTA)[edit]

The Los Angeles Metro Rail system is an amalgamation of two former constituent companies, the Los Angeles County Transportation Commission and the Southern California Rapid Transit District; both of those companies were responsible for planning the initial system. It is composed of two heavy rail subway lines and several light rail lines with subway sections; while all lines are standard gauge, inconsistencies in electrification and loading gauge prohibit the light rail trains from operating on the heavy rail lines, and vice versa. The LACTC-planned Blue Line was opened in 1990 and partially operates on the route of the Pacific Electric interurban railroad line between downtown Los Angeles and Long Beach, which used overhead electrification and street-running streetcar vehicles. The SCRTD-planned Red Line (later split into the Red and Purple lines) was opened in 1993 and was designed to handle high-capacity heavy rail transit cars that would operate underground. Shortly after the Red Line began operations, the LACTC and the SCRTD merged to form the LACMTA, which became responsible for planning and construction of the Green, Gold, Expo, and Crenshaw lines, as well as the Purple Line Extension and the Regional Connector.

Broad gauge[edit]

Some rapid transit lines in North America, notably Bay Area Rapid Transit, which uses 5 ft 6 in (1,676 mm) broad gauge track rather than 4 ft 8 1⁄2 in (1,435 mm) standard gauge track.

Narrow gauge[edit]

Narrow gauge railways generally have a smaller loading gauge than standard gauge ones, and this is a major reason for cost savings rather than the track gauge itself.

Structure gauge[edit]

The structure gauge, which refers to the dimensions of the lowest and narrowest bridges or tunnels of the track, complements the loading gauge, which specifies the tallest and widest allowable vehicle dimensions. There is a gap between the structure gauge and loading gauge, and some allowance needs to be made for the dynamic movement of vehicles (sway) to avoid mechanical interference causing equipment and structural damage.

The Structure gauge is always larger than the Loading gauge.

Out of gauge[edit]

Larger out-of-gauge loads can also sometimes be conveyed by taking one or more of the following measures:

- Operate at low speed, especially in places with limited clearance, such as platforms.

- Cross over from a track with inadequate clearance to another track with greater clearance, even if there is no signalling to allow this.

- Prevent operation of other trains on adjacent tracks.

- Use refuge loops to allow trains to operate on other tracks.

- Use of Schnabel cars (special rolling stock) that manipulate the load up and down or left and right to clear obstacles.

- Remove (and later replace) obstacles.

- Use gauntlet track to shift the train to side or center.

- For locomotives that are too heavy, ensure that fuel tanks are nearly empty.

- Turn off power in overhead wiring or in the third rail.

While it may be true that trains of a particular loading gauge can travel freely over tracks of a matching structure gauge, in practice, problems can still occur. In an accident at Moston station, an old platform not normally used by freight trains was hit by a train that wasn't within its intended W6a gauge because two container fastenings were hanging over the side. Analysis showed that the properly configured train would have passed safely even though the platform couldn't handle the maximum design sway of W6a. Accepting reduced margins for old construction is normal practice if there have been no incidents but if the platform had met modern standards with greater safety margin the out of gauge train would have passed without incident.[19][20][21]

Trains larger than the loading gauge, but not too large, can operate if the structure gauge is carefully measured, and the trip is subject to various special regulations.

Gallery[edit]

See also[edit]

References[edit]

- ↑ "Glossary". NetworkRail.co uk. Network Rail. Archived from the original on 6 May 2009. Retrieved 15 May 2009. Unknown parameter

|url-status=ignored (help) - ↑ 2.0 2.1 2.2 2.3 2.4 2.5 2.6 Association of American Railroads; Mechanical Division (15 May 1966). "Car and locomotive cyclopedia of American practice". Car and Locomotive Cyclopedia of American Practice. OCLC 5245643.

- ↑ Clearance maps for CSX, a typical major carrier Archived 10 December 2012 at the Wayback Machine

- ↑ "Comparaison des gabarits UIC et nord-américains (Comparison of UIC and North American Gauges)". Marc Dufour. Archived from the original on 12 September 2009. Retrieved 16 October 2009. Unknown parameter

|url-status=ignored (help) - ↑ April 2001 Official Railway Equipment Register "Archived copy" (PDF). Archived from the original (PDF) on 9 May 2013. Retrieved 23 November 2012. Unknown parameter

|url-status=ignored (help)CS1 maint: Archived copy as title (link) "Archived copy" (PDF). Archived from the original (PDF) on 1 April 2010. Retrieved 23 November 2012. Unknown parameter|url-status=ignored (help)CS1 maint: Archived copy as title (link) - ↑ Guide to Railcars

- ↑ 89 ft (27.1 m) flat car[dead link]

- ↑ Guide to Railcars

- ↑ Autorack[dead link]

- ↑ Guide to Railcars >tp://worldtraderef.com/WTR_site/Rail_Cars/Guide_to_Rail_Cars.asp Archived 31 October 2011 at the Wayback Machine

- ↑ Autorack[dead link]

- ↑ Guide to Railcars >tp://worldtraderef.com/WTR_site/Rail_Cars/Guide_to_Rail_Cars.asp Archived 31 October 2011 at the Wayback Machine

- ↑ "Railway line clearances and car dimensions including weight limitations of railroads in the United States, Canada, Mexico and Cuba". Railway Line Clearances and Car Dimensions Including Weight Limitations of Railroads in the United States, Canada, Mexico and Cuba. OCLC 10709088.

- ↑ Dufour, Marc. "CoupeTunnelDouble". La ligne de banlieue Montréal – Deux-Montagnes & le réseau ferré de banlieue. Archived from the original (GIF) on 10 October 2007. Retrieved 13 May 2008. Unknown parameter

|url-status=ignored (help) - ↑ "NYC Fun Facts: Not All NYC Subway Trains Are the Same Size". Untapped Cities. 2 August 2017. Retrieved 11 July 2018.

- ↑ Second Avenue Subway Draft Environmental Impact Statement, "Glossary" (PDF). (45.6 KiB)

- ↑ Clarke, Bradley (1981). The Boston Rapid Transit Album. Cambridge, Mass.: Boston Street Railway Association. p. 8. Search this book on

- ↑ Fischler, Stanley I. (1979). Moving millions : an inside look at mass transit (1st ed.). New York: Harper & Row. ISBN 0-06-011272-7. Search this book on

- ↑ The Railway Magazine April 2015, p12

- ↑ "Here is a platform alteration". rail.co.uk. 17 February 2015. Archived from the original on 20 August 2016. Unknown parameter

|url-status=ignored (help) - ↑ "Report 17/2015: Trains struck platform at Moston, Manchester". gov.uk. Rail Accident Investigation Branch. 7 October 2015. Archived from the original on 24 September 2016. Unknown parameter

|url-status=ignored (help)

Further reading[edit]

- Jane's World Railways yearbook contains many though not all loading gauge diagrams.

External links[edit]

- 2002/732/EC: Commission Decision of 30 May 2002 concerning the technical specification for interoperability relating to the infrastructure subsystem of the trans-European high-speed rail system

- Berne and all that (1992 diagram of European loading gauges) at crowsnest.com (Images do not open)

- AAR "plate" loading gauge diagrams compared to UIC (pdf & Autocad)

- Railway Loading Gauges at Joyce's World of Transport Eclectica Archived 6 October 2014 at the Wayback Machine

- Loading Gauges at The Self Site

- UIC Leaflets

- Railway industrial Clearance Association

- British Track Gauge & Loading Gauge

- APTA PR-CS-RP-003-98

- Railway line clearances and car dimensions including weight limitations of railroads in the United States, Canada, Mexico and Cuba.

- AAR plates with UIC

- Guide to Rail Cars

This article "Railroad Loading Gauge in North America" is from Wikipedia. The list of its authors can be seen in its historical and/or the page Edithistory:Railroad Loading Gauge in North America. Articles copied from Draft Namespace on Wikipedia could be seen on the Draft Namespace of Wikipedia and not main one.