Performance fabrics

Performance fabrics are a segmented class (Clothtech[1]) of technical textiles with the specific aim of providing functional clothing[2], and thereby enhancing the "performance" of various natural and synthetic fibres. Fabrics with certain functionalities take into account user-specific needs like protection, anthropometry, psychological[3] and thermo-physiological[4] considerations, especially under intense conditions, fall under this category.

Traditional fabrics are unable to comply with all necessary usage parameters, especially when the exposure is unusual and severe. Examples in this regard are intensive physical activities such as exercise, running, sports, exposure to extreme weather, U.V. radiation, tactical-combat situations, fire, and so on. Normally, properties of various fabrics depend upon the inherent characteristics of the constituent fibre, which maybe natural or synthetic. Their characteristics are often based upon the source of origin and polymer structure, respectively. Singular use of these fibres can help achieve many of these parameters but not all, thus, for missing attributes and to extend their functionality and for use in severe conditions, they are treated with different methods and industrial procedures to add the desired additional functionalities. These fabrics are called performance fabrics and are known to perform multiple functions.[5][6][7][8][9][10]

Methods of manufacturing[edit]

The performance of the fabrics is improved and attained by various methods of production, including blending of fibres[11] during spinning, knitting or weaving by using multiple yarn like cotton, wool,[12] viscose, bamboo, polyester, acrylic, nylon, and elastane, and also by processing and finishing with chemicals (also known as functional finishes)[13][14] during dyeing or at finishing stages.[citation needed]

Nanotechnology can provide high durability for performance fabrics, because nanoparticles have a large surface area-to-volume ratio and high surface energy, thus presenting better affinity for fabrics and leading to an increase in durability of the function. The potential of nanotechnology in the development of new materials in the textile industry is considerable. On the one hand, existing functionality can be improved using nanotechnology, and on the other, it could make possible the manufacture of textiles with entirely new properties or the combination of different functions in one textile material[15]

Characteristics[edit]

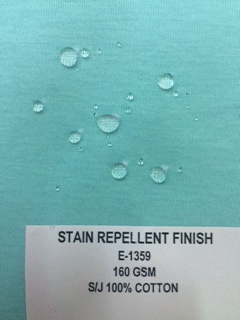

The different performance fabrics have various functionalities engineered to meet requirements and end use. Mainly they are protective, sports functional, and for hygiene and heathcare. Different functions makes them suitable for different applications and areas. Some varieties of performance fabrics are capable of blocking harmful ultraviolet radiation,[16] and they often have protection from ticks and mosquitoes, moisture wicking, Quick Dry, temperature control, and antimicrobial and anti-odor properties.[17][18][19] Performance fabrics may also possess pilling-resistance, wrinkle resistance, and stain (water, dirt, and oil) resistance, and be antistatic, self-cleaning,[15][20] and flame resistant.[21][19] In some cases, they can be resistant to wind, heat, and abrasion. The revenue of the performance fabrics market is projected to grow at 20.18% per year during 2014–2019.[22] For example, a polyester garment can absorb water like cotton, and a cotton trouser can gain the ability to repel water,[23] even though both of these characteristics differ from their original nature. Smart textiles and wearable technologies are advanced performance fabrics.[24]

See also[edit]

References[edit]

- ↑ "TECHNICAL TEXTILES | Home". www.technotex.gov.in. Retrieved 2018-08-17.

- ↑ Gupta, Deepti (2011-12-01). "Functional clothing-Definition and classification". Indian Journal of Fibre and Textile Research. 36: 321–326.

- ↑ Harms, Ernst (1938). "The Psychology of Clothes". American Journal of Sociology. 44 (2): 239–250.

- ↑ Psikuta, Agnes; Annaheim, Simon; Rossi, René M. (2017-01-01). "Thermo-physiological simulation". Manikins for Textile Evaluation: 331–349. doi:10.1016/B978-0-08-100909-3.00015-7.

- ↑ "Performance Textiles and Fabrics: Assessing and Verifying Product Performance Claims" (PDF).

- ↑ Kawabata, S.; Niwa, Masako (January 1989). "Fabric Performance in Clothing and Clothing Manufacture". The Journal of The Textile Institute. 80 (1): 19–50. doi:10.1080/00405008908659184. ISSN 0040-5000.

- ↑ "Dunning Golf". coolmax.com. Retrieved 2018-08-16.

- ↑ Milliken. "Performance Fabrics | Stain, Moisture, Medical, Textiles | Milliken". www.milliken.com. Retrieved 2018-08-16.

- ↑ "About Performance Fabrics". Retrieved 2018-08-16.

- ↑ "Performance Fabrics". Revolution Performance Fabrics. Retrieved 2018-08-16.

- ↑ Suzuki, Togi; Ishimaru, Sonoko (2016), "Moisture and Water Control Man-Made Fibers", High-Performance and Specialty Fibers, Springer Japan, pp. 247–260, ISBN 9784431552024, retrieved 2018-08-12

- ↑ McNaull, Cindy (2017). "Three Trends Driving Wool Fashions". AATCC Online. Retrieved 2018-08-12.

- ↑ "Functional Finishes and Coatings for Performance Textiles". American Association of Textile Chemists and Colorists. Archived from the original on October 17, 2013.

- ↑ "Performance Enhancement of Textile Fabrics" (PDF). American Association of Textile Chemists and Colorists. Archived from the original (PDF) on April 20, 2014.

- ↑ 15.0 15.1 "Nanotechnology textiles". Nanowerk.com. 16 December 2010. Retrieved 15 August 2018.

- ↑ "Players to wear special caps for Midsummer Classic in ode to Cincinnati baseball". The Highland County Press. 17 June 2015. Retrieved 22 August 2015.

- ↑ "Antibacterial & Odor Control: Marketing and Technology Advancements Conference". American Association of Textile Chemists and Colorists. Archived from the original on May 12, 2015.

- ↑ Fetters, K. Aleisha (11 April 2015). "Are You Washing Your Workout Clothes Properly?". Huffington Post. Retrieved 22 August 2015.

- ↑ 19.0 19.1 Easter, Elizabeth P. (June 2008). "High-performance fabrics for commercial upholstery". Upholstery Journal. Industrial Fabrics Association International. Retrieved 22 August 2015.

- ↑ "Self-cleaning cotton nanoparticle coating invented". BBC.

- ↑ Claudia Ollenhauer (September 2013). Personal Protection Textiles (2nd ed.). ISBN 978-0-9573-6163-8. Search this book on

- ↑ ltd, Research and Markets (July 2015). "Global Smart Fabrics and Textiles Market 2015-2019".

- ↑ Evans, John (24 November 2008). "Nanotech clothing fabric 'never gets wet'". New Scientist. Retrieved 15 August 2018.

- ↑ "RIL and Arvind join hands to make high performance fabrics". The Economic Times.

This article "Performance fabrics" is from Wikipedia. The list of its authors can be seen in its historical and/or the page Edithistory:Performance fabrics. Articles copied from Draft Namespace on Wikipedia could be seen on the Draft Namespace of Wikipedia and not main one.